Production/Manufacturing Tracking

The strength of the system is the ability to track the manufacture of the products, including multiple machines and outside processing. This is the part of e-Insight ERP that separates us from the competition – we handle the production flow for this environment.

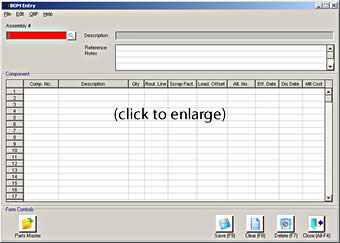

Bill of Materials:

Although the input for the production is straight forward, we still provide the options for multiple items and levels for Bills of Material. This allows your business tremendous flexibility in how you define your part production.

Although the input for the production is straight forward, we still provide the options for multiple items and levels for Bills of Material. This allows your business tremendous flexibility in how you define your part production.

Key Features

- Enter Part Number then start adding components for the product

- Multi-level possible

- Enter Quantity required, Routing, Lead times, Alternate numbers, effective date, discontinued date, material cost

- Enter Reference Notes as needed.

- Generate Exploded BoM reports

- Handles simple ‘kitting’ or complex combinations

Routing:

The Routing portion of the system allows you to define the flow through the system for your production – what operation is first, where the part goes next, and even to outside processors.

Key Features

- Enter Route information including Production Line Number

- Work Center Assigned

- Operations for processing

- Labor Time expected

- Notes by Line

- Re-sequence Lines when needed

Work Centers:

The system allows for the designation of Work Centers – these can be single machines or can be several machines in a department. It is up to you to implement the system in a manner that is best for your organization.

Key Features

- Enter Work Center name and description

- Total hours available

- Labor accounts plus rate per hour if known and needed.

Operations:

You can define various Operations that must be tracked by the system. The estimated times to perform the task can be entered to set up standards for tracking against.

Key Features

- Enter Operation Id and Description

- Time to perform the task, add the rate id for costing, type of operation.

- Where Used Lookup form to see where the item is used.

Resources Entry:

Resources can be defined to further enhance your ability to set up production standards for your business.

Key Features

- Use to enter other resources available to use – enter id and full description, include burden percentages and amounts

- Resources can be machines, people, etc.

Rates Entry:

Rates can be assigned to any machine or position so that a specific hourly rate can be used by the system to calculate standard costs versus actual costs.

Key Features

- Use this to assign hourly rates to equipment including any overhead percentages

- Use to assign hourly rates for employee positions

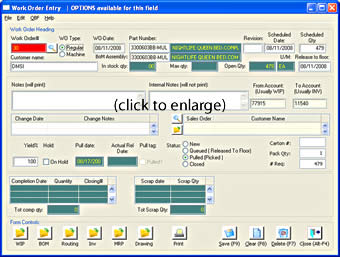

Work Orders:

Work Orders:

Work Orders are used to tell the production department what part needs to be produced, how many and by what date.

Key Features:

- Use to create the Work Order for a Scheduled Date and quantity.

- Use Multiple Notes fields to enter details for producing the product – some will print on the Work Order form, others are for internal system use.

- Track Changes

- Allow you to see completion information including total completed quantities

- Easily see related Work In Process, Bill of Materials, Routings, Inventory, MRP and Drawings from mouse clicks on buttons.

Close Work Orders:

Once the production is completed, this form is used to document the results and to close the work order so the system knows the change of status.

Key Features

- Easily done, assigns a closing number associated with the work order number.

- Displays details on Warehouse and quantities of completed products, and see raw material details.

- Enter the Lot Number for the Work Order here

- Report the completed quantities

There is a lot more to the Production portion of e-Insight ERP that has been described above. One very important portion is the Active MRP – instead of having to constantly run an MRP calculation, the system can be configured to actively update the MRP as Sales Orders, Purchase Orders, Invoicing, Receiving and Shipping are going on. This interactive process sets e-Insight ERP apart from all other applications in this price range. This allows you the user to check what needs to be ordered immediately instead of having to run a process that could take hours in order to get the results that you will see immediately.

Additionally, if you wish, e-Insight ERP can be configured to run a manual MRP process, or re-generate an MRP from the interactive MRP at any time. Flexibility is the key to how we have implemented the MRP process within this solution.

Next: Financial/Accounting Features ->

Please contact us for further information or a demo.

OpenInsight is a trademarked product of Revelation Software,

Westwood, NJ

e-Insight ERP licensed from InsiTech Group LLC. Cheshire, CT.